single phase motor wiring diagram with capacitor start pdf

single phase motor wiring diagram with capacitor start pdf

Capacitor start motors utilize a capacitor to boost starting torque, essential for single-phase induction applications. Understanding their wiring, often found in PDF diagrams, is crucial.

What is a Capacitor Start Motor?

Capacitor start motors are a specific type of single-phase induction motor designed to generate a significant starting torque. They achieve this by incorporating a capacitor within the auxiliary (or starting) winding circuit. This capacitor introduces a phase shift between the currents flowing through the main and auxiliary windings, effectively creating a temporary two-phase system during startup.

This phase difference is vital because single-phase motors inherently lack the starting torque of three-phase motors. The capacitor boosts the magnetic field, enabling the motor to overcome static friction and initiate rotation. Once the motor reaches a certain speed – typically around 75% of its rated speed – a centrifugal switch disconnects the capacitor and auxiliary winding from the circuit, allowing the motor to run solely on the main winding. Detailed wiring diagrams, often available as PDF documents, illustrate this process clearly, showing the capacitor’s placement and the function of the centrifugal switch.

Applications of Capacitor Start Motors

Capacitor start motors excel in applications demanding high starting torque and intermittent duty cycles. Common uses include compressors, pumps, conveyors, and various industrial machinery where initial load is substantial. They are frequently found in HVAC systems, powering fan motors and compressor units. Their ability to self-start under load makes them ideal for equipment that isn’t constantly running.

Understanding the wiring diagram – often accessible as a PDF – is crucial for proper installation and maintenance in these applications. Because of their widespread use, numerous resources detail specific wiring configurations for different horsepower ratings and voltage requirements. Troubleshooting often involves checking the capacitor and centrifugal switch, referencing the diagram to ensure correct connections. The motor’s efficiency and reliability are directly linked to accurate wiring and component functionality.

Understanding the Wiring Diagram

A clear wiring diagram, often a PDF, is vital for safely connecting a capacitor start motor, identifying terminals, and understanding component interactions.

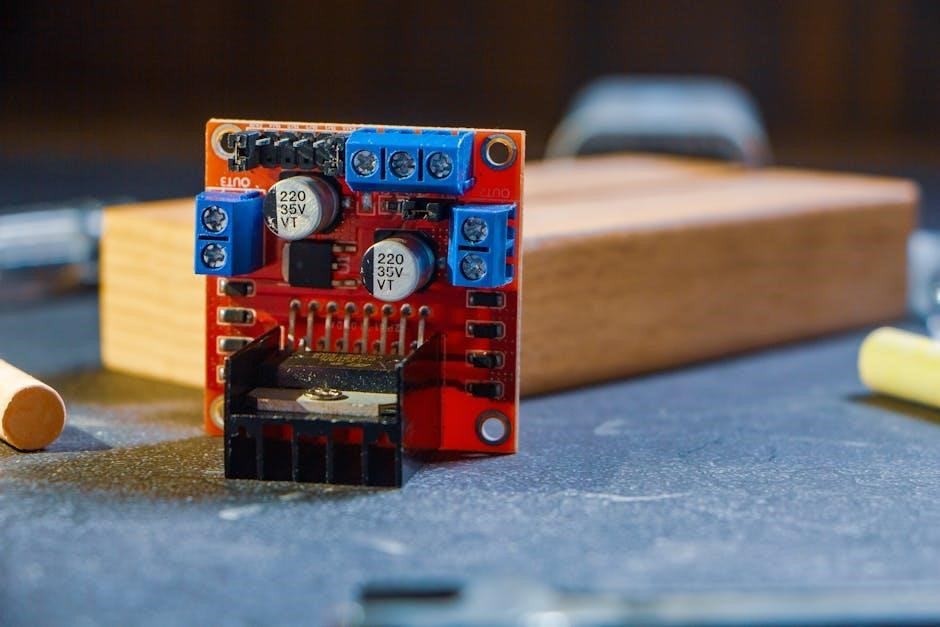

Key Components in the Circuit

The core of a capacitor-start motor circuit revolves around several key components. Naturally, the single-phase motor itself is central, featuring main and auxiliary windings. A start capacitor, crucial for initial torque, is wired in series with the auxiliary winding. Often, a centrifugal switch disconnects this capacitor once the motor reaches a certain speed.

Furthermore, a run capacitor might be present for improved efficiency, connected permanently to one winding. Motor terminals (U, V, W, etc., or R, S, C) define winding connections. A contactor or switch provides power to the circuit, and appropriate fuses or circuit breakers ensure safety. Examining a detailed PDF wiring diagram reveals how these elements interact, highlighting terminal markings like FAN, HERM, and COM, commonly found in HVAC applications.

Identifying Motor Terminals (U, V, W, etc.)

Decoding motor terminal markings is vital when referencing a single phase motor wiring diagram with capacitor start, often found as a PDF. Common designations include U, V, W for the main windings, and sometimes separate terminals for the auxiliary winding. HVAC motors frequently use R (Run), S (Start), and C (Common) labels. Understanding these is key to correct wiring.

Color coding assists identification, though variations exist. A PDF diagram should clearly indicate the corresponding wire colors for each terminal. Terminals labeled F (Fan), H (Herm/Compressor), and COM (Common) are typical in HVAC systems. Accurate identification prevents miswiring, ensuring proper motor operation and avoiding damage. Always cross-reference the diagram with the motor’s nameplate for definitive terminal assignments.

Capacitor Selection and Ratings

Capacitor values (µF) and voltage ratings are critical; a PDF wiring diagram specifies these. Oil-filled and electrolytic types are common choices for optimal performance.

Capacitance Value (µF) and Voltage Rating

Determining the correct capacitance, measured in microfarads (µF), is paramount for successful motor starting. A single phase motor wiring diagram, often available as a PDF, will clearly indicate the required µF value for both the start and run capacitors, if applicable. Selecting a capacitor with an insufficient µF rating will result in reduced starting torque and potential motor failure.

Equally important is the voltage rating of the capacitor. This rating must exceed the maximum voltage the capacitor will experience during operation. Referencing the motor’s nameplate and the wiring diagram will reveal the appropriate voltage rating. Using a capacitor with a lower voltage rating can lead to capacitor failure, potentially causing damage to the motor and creating a safety hazard. Always prioritize matching the specifications outlined in the motor’s documentation and associated PDF schematics.

Types of Capacitors Used (Oil-filled, Electrolytic)

Capacitor start motors commonly employ two primary capacitor types: oil-filled and electrolytic. Oil-filled capacitors, known for their robustness and reliability, are frequently used as run capacitors due to their ability to withstand continuous operation. However, electrolytic capacitors, while more compact and offering higher capacitance for their size, are typically reserved for start applications due to their limited lifespan under constant AC voltage.

A single phase motor wiring diagram, often found as a PDF, won’t usually specify the type but will detail the required µF and voltage. When replacing capacitors, understanding these differences is crucial. Incorrectly substituting an electrolytic capacitor for a run capacitor will likely result in premature failure. Always consult the motor’s documentation and a reliable wiring diagram to ensure the correct capacitor type is used, safeguarding motor performance and longevity.

Wiring Diagram Breakdown ⎯ Step-by-Step

PDF diagrams illustrate connecting the start capacitor across auxiliary winding coils, then the main winding to power, ensuring correct phase shift for starting.

Connecting the Start Capacitor

Referencing a single phase motor wiring diagram with capacitor start (often found as a PDF), the start capacitor is crucially connected in parallel with the auxiliary winding. This connection provides the necessary phase shift for initial torque production. Typically, you’ll identify the auxiliary winding terminals – often labeled or discernable through tracing – and securely attach the capacitor leads.

Ensure proper polarity if the capacitor is polarized (electrolytic types). Incorrect connection can damage the capacitor or prevent starting. The 2.5uF capacitor, as mentioned in practical scenarios, exemplifies a common value. Carefully examine the PDF diagram for specific terminal markings (U, V, W, etc.) and wire colors to avoid miswiring. A secure connection is vital for reliable operation, and double-checking against the diagram is always recommended.

Connecting the Run Capacitor (if applicable)

Not all capacitor-start motors include a run capacitor; however, if your single phase motor wiring diagram with capacitor start (PDF) indicates one, it’s connected differently than the start capacitor. The run capacitor remains in the circuit continuously during operation, improving efficiency and power factor. It’s typically wired in series with the auxiliary winding, not in parallel like the start capacitor.

Look for terminals labeled ‘RUN’ or ‘C’ (Common) on the motor and capacitor. Proper connection is vital; incorrect wiring can lead to reduced performance or motor damage. HVAC motor diagrams often use ‘F’ (Fan), ‘H’ (Herm/Compressor), and ‘C’ (Common) designations. Always verify the capacitor’s voltage rating matches or exceeds the motor’s voltage. Refer closely to the PDF diagram for precise terminal connections and wire color coding.

Main Winding Connections

The main winding, often referred to as the running winding, receives direct voltage and is responsible for sustaining the motor’s rotation. Your single phase motor wiring diagram with capacitor start (PDF) will typically show the main winding connected directly to the power source – usually the line and neutral wires. Terminals are commonly labeled ‘U’ and ‘V’, or ‘L’ and ‘N’ representing Line and Neutral respectively.

Ensure a secure and properly insulated connection to prevent shorts or overheating. The wire gauge must be appropriate for the motor’s current draw, as specified in the PDF documentation. Some diagrams may include a thermal overload protector in series with the main winding for safety. Double-check the wiring against the diagram before energizing the motor, verifying correct phase relationships for optimal performance.

Auxiliary Winding Connections

The auxiliary winding, or starting winding, is crucial for initiating rotation in a capacitor-start motor. Your single phase motor wiring diagram with capacitor start (PDF) will illustrate this winding connected in parallel with the start capacitor. Terminals are often labeled ‘W’ and ‘X’, or sometimes ‘S’ for Start. This winding creates a phase shift, generating the necessary starting torque.

Crucially, the auxiliary winding is only energized during startup and is typically disconnected by a centrifugal switch once the motor reaches a certain speed. The PDF diagram will clearly show the switch’s placement. Incorrect wiring here can prevent starting or damage the motor. Verify the capacitor is correctly connected across the auxiliary winding terminals before applying power, referencing the diagram meticulously.

Troubleshooting Common Wiring Issues

Refer to your single phase motor wiring diagram (PDF) to pinpoint faults. Common issues include a failed capacitor or a disconnected winding.

Motor Doesn’t Start

If a capacitor-start motor fails to initiate, meticulously review the single phase motor wiring diagram (PDF). First, verify power reaches the motor itself; a simple continuity test can confirm this. Next, critically assess the start capacitor – a common failure point. Use a capacitance meter to confirm it’s within its rated µF value.

Inspect all wiring connections, ensuring they are secure and free from corrosion. A loose connection can easily prevent startup. Check the centrifugal switch; it should engage and disengage the start winding correctly. If the switch is faulty, the start capacitor remains in the circuit too long, or not long enough. Finally, examine the auxiliary winding for open circuits using a multimeter. A broken winding will prevent the motor from generating the necessary starting torque.

Motor Runs Slowly or Weakly

When a capacitor-start motor operates with reduced power, consult the single phase motor wiring diagram (PDF) for accurate troubleshooting. A weakening run capacitor (if present) is a prime suspect; test its capacitance and voltage rating. Low values indicate degradation. Verify the start capacitor is correctly sized and functioning, as it influences initial torque and can impact running performance.

Inspect the motor windings for shorts or partial opens, using a multimeter to check resistance. Low resistance readings suggest a short, while high or infinite resistance indicates an open winding. Also, confirm proper voltage supply to both the main and auxiliary windings. Reduced voltage will inevitably lead to diminished performance. Finally, check for mechanical loads exceeding the motor’s capacity.

Safety Precautions

Always disconnect power before working with wiring. Capacitors store energy – discharge them properly! Refer to the PDF wiring diagram for safe practices.

Working with Electricity

Electrical safety is paramount when dealing with capacitor start motor wiring. Before attempting any connections, always disconnect the power supply at the circuit breaker or fuse box. Verify the power is off using a reliable voltage tester. Never assume a wire is de-energized; treat all wires as live until proven otherwise.

When referencing a PDF wiring diagram, understand that diagrams are representations and real-world wiring may have slight variations. Use insulated tools specifically designed for electrical work. Avoid working in damp or wet conditions, as water significantly increases the risk of electric shock. If you are uncomfortable or unsure about any aspect of the wiring process, consult a qualified electrician. Proper grounding is essential for safety and preventing equipment damage.

Capacitor Discharge Procedures

Capacitors store electrical energy even after power is removed, posing a shock hazard. Before handling or disconnecting any capacitor referenced in a PDF wiring diagram, it must be safely discharged. Use a properly insulated screwdriver with an insulated handle and a resistor (typically 10kΩ to 20kΩ, rated for the capacitor’s voltage) to short across the capacitor terminals.

This slowly dissipates the stored energy. Never use a direct short circuit, as this can cause sparks and damage the capacitor. Verify complete discharge with a multimeter before touching the capacitor. Repeat the discharge process periodically if the capacitor sits unused for a while. Always exercise caution and treat capacitors with respect, even after discharge, as some residual charge may remain.

Resources and Further Information

Numerous PDF wiring diagrams and online forums offer valuable insights into capacitor start motor connections and troubleshooting, aiding successful repairs.

Where to Find Wiring Diagrams (PDFs)

Locating reliable wiring diagrams for capacitor start single-phase motors often begins with manufacturer websites. Many companies provide downloadable PDF schematics for their specific motor models. A targeted Google search using terms like “capacitor start motor wiring diagram PDF” or “[Motor Brand] wiring diagram” yields numerous results.

Electrical engineering websites and forums frequently host user-submitted diagrams and discussions. Websites specializing in HVAC equipment often contain diagrams relevant to capacitor-start motors used in pumps and fans. Additionally, document sharing platforms may have collections of motor wiring schematics. Always verify the diagram’s accuracy against your motor’s nameplate information and consult a qualified electrician if unsure about any connection.

Online Forums and Communities

Engaging with online forums and communities dedicated to electrical engineering and DIY repairs can be invaluable when seeking a capacitor start motor wiring diagram. Platforms like ElectricianTalk, DIY Electrical, and specific HVAC forums often feature threads discussing motor wiring challenges. Users frequently share PDF diagrams and offer practical advice based on real-world experience.

These communities allow you to post specific questions about your motor model and receive tailored guidance. Remember to provide detailed information, including the motor’s horsepower, voltage, and any markings on the capacitor. Always critically evaluate advice received online and prioritize safety; consulting a qualified electrician remains crucial for complex or uncertain wiring scenarios.